Ferrous Castings

- Home

- Ferrous Castings

Our Parent company SPB New Alloy Steel Private limited is located at outskirts of Coimbatore on NH209 towards Annur.The Annual cpacity of the 2400 MT good casting ,We have the capability to Manufacture the castings in weight range between 15Kg to 2500 Single piece in Machined and Rough casting condition.

We’ve partnered with thousands of client providing them with some of the best casting components for their industrial needs. Since we always use specialised methods to work on various forms of raw materials, we are able to manufacture high-quality castings in large quantities.

We can provide regular and custom casings to our customers as a leading name in India when it comes to the manufacturing of various industrial components.Our goods are available to consumers not only in India, but also around the world.

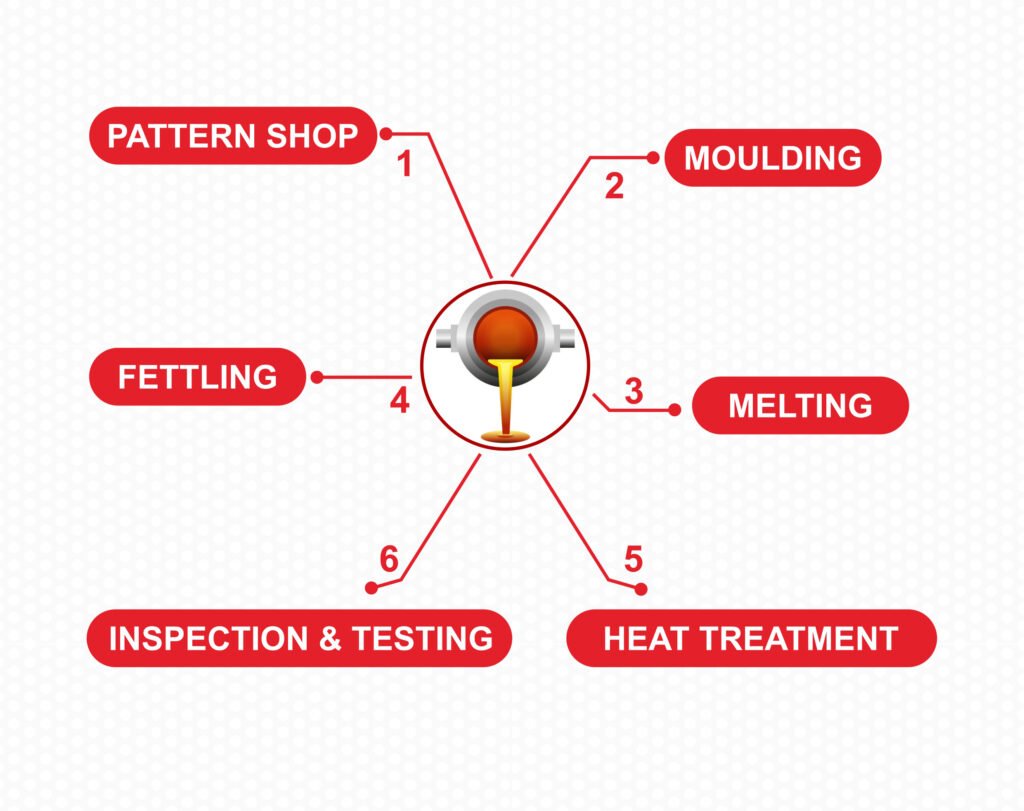

FACILITIES

MELTING

- Medium Frequency Inductotherm

- Induction Furnace

- Power rating 750 Kw

- Melting Crucibles – 3000 kg 1 No & 500 kg – 1 No

- Maximum Weight of the Liquid Metal – 4250 Kgs

- 3 MT Bottom Pouring Ladle – 1 No

- 600 kg Gear Ladle – 2 No

- 200 kg Hand Shank – 1 No

- Lip Pouring Ladles Available to Suit the Requirements

- Standard and portable pyrometer for temperature measurement

MOULDING

- Co2 sodium silicate process , denoted ( Airset process ) & No bake process

- Sand mixing – muller 500 kgs – 1 No & mixer 250 kgs – 3no , 50 kgs – 1 no

- Sand mixing 2MT /Hr Hand moulding box 1000 mm min and 2300 mm max

- Hand moulding box 1000 mm min and 2300 mm max

- box moulding , cake moulding and pit moulding

HEAT TREATMENT

- Furnace type – LPG Gas fired & Electric

- Electrically Operated Heat Treatment

- Capacity 5 MT / 1.5 MT • Rate of heating 150/100° Celsius per hour

- Chamber size – 1.5 MT ( 18000mm L x 1000mm W x 1000mm H )

- Chamber size – 5 MT (2800MM L x 1500mm W x 1300mm H )

- Maximum temperature 1200°

- 9 Zones

- PID Controller

- Computerised paperless recorder

- Processes – Normalising , Annealing , Solution annealing , Stress Relieving , water Quenching

- facilities – 50000 litres water capacity with cooling tower

FETTLING FACILITIES

- Fettling Unit with Shot Blasting Machine

- Swing Grinders – 2 Nos

- Flexible Shaft Grinders – 19 Nos

- Pneumatic Grinders – 2 Nos

- Die grinder – 2 No

CASTING UPGRADATION

- Welding Inverter 600 Amps – 5 No

- Welding Inverter 600 Amps – 1 No

- Electrode preheating flask oven 120° maintained

NON-DESTRUCTIVE EVALUATION

- Dye penetrate kit – water washable & solvent removable

- Magnetic particle inspection – MPI 8000 Amps with PROD Technique & AC Yoke

- Approved sub contractors for radiography

INSPECTION AND TESTING

- Spectro Maxx Spectrometer

- Sieve shaker sand testing

- 27 elements including Nitrogen for Iron Base and Nickel Base, Copper base

- Electronic Universal Testing Machine – 40 tons capacity

- Impact Testing Machine

- Brinell Hardness Testing Machine

- Magnetic Field Testing

- Portable hardness tester & shear pin hardness tester

- NDT ( Level II Qualified personal in RT,UT,MT, PT and VT )

MATERIAL HANDLING AND OTHER EQUIPMENTS

- EOT Crane 10 MT – 1 No

- Overhead Crane 7.5 MT – 1 No

- Overhead Crane 5 MT – 3 No

- Overhead Crane 3 MT -1 No

- Mobile crane – 12 MT

- 30 HP Compressors – 2 No

- Standby power Genset 500KVA – 1 No

- Mulfle furnace available

PRESSURE CL RATINGS

- Minimum 150 Class

- Maximum 5000 Class

OUR CAPABILITIES

- Minimum weight – 15 kg

- Maximum weight – 2500 kg

- Supply condition – Unmachined / Machined